Digital microscopy

Polyepheline tubes qc tool based on image analysis

Technologies

Business challenge

We had to create the method that will be applicable to polyolen pipes and fittings, as well as raw material in pellet form, with the choice of procedure to be determined by the referring specification. The method should be applicable to carbon black pigmented polyolen pipes, fittings and compounds with a carbon black content of less than 3%.

Result

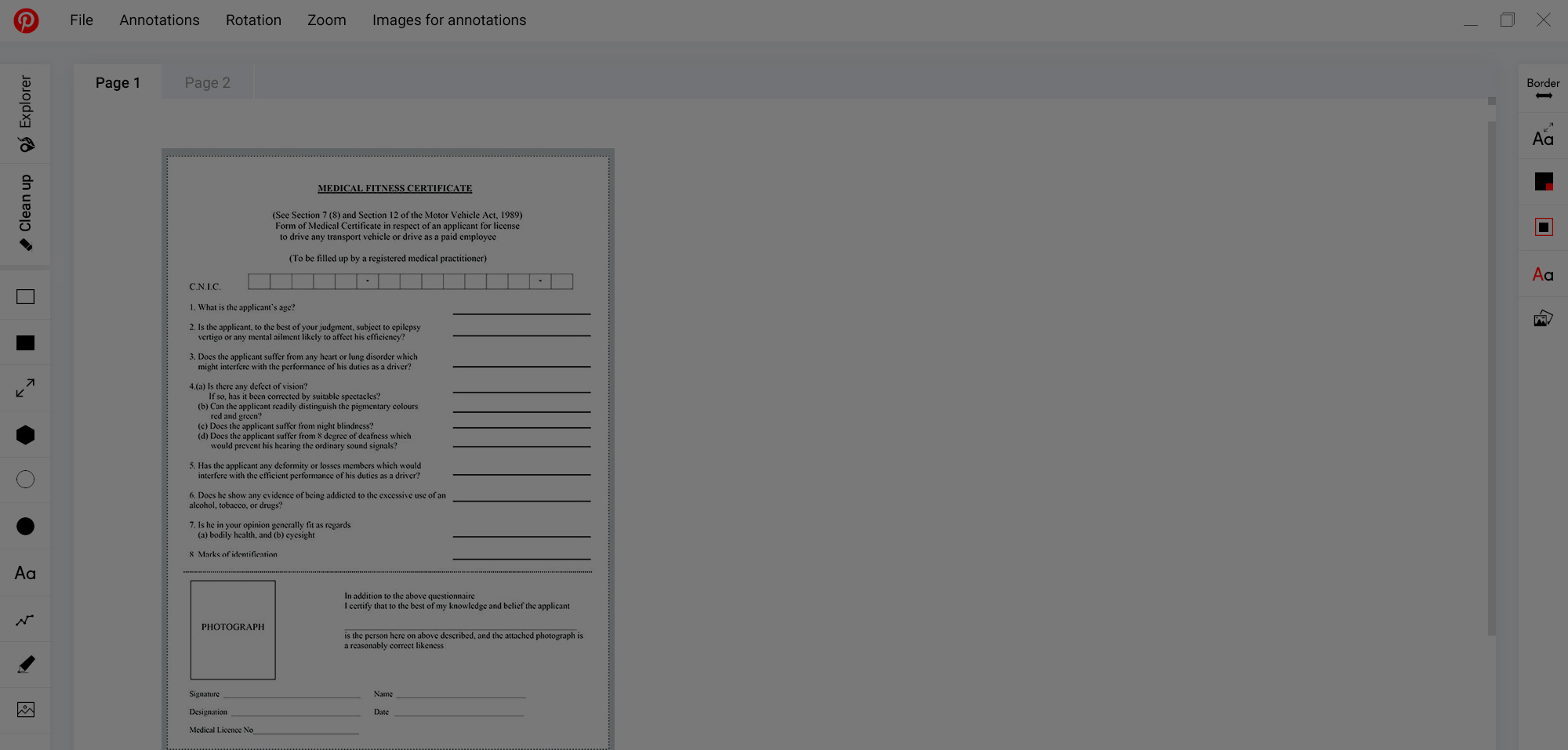

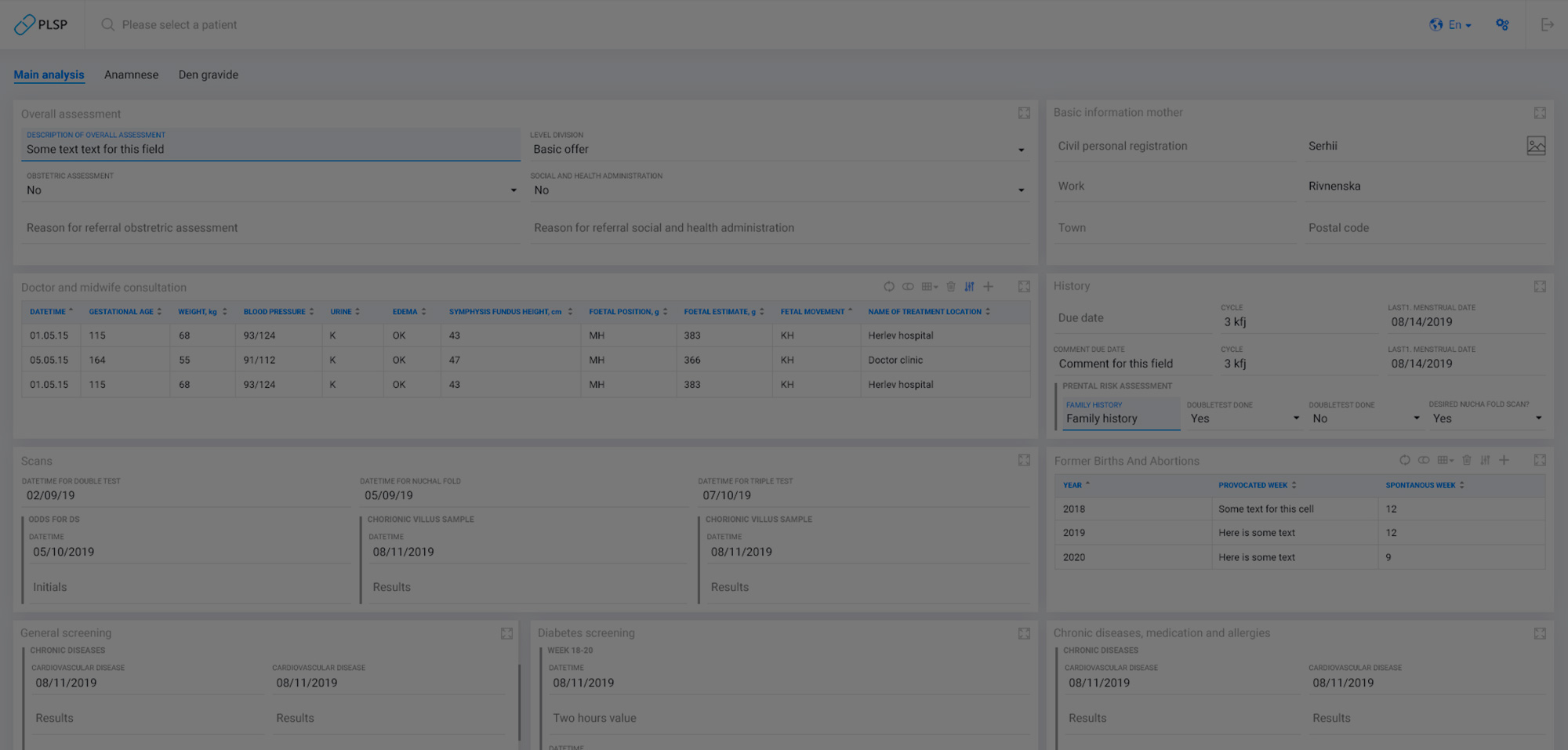

Our team prepared user friendly, powerful and highly adaptive software with unique concept based on ISO methodology with fully automatic and semi automatic inspection. Small samples of raw-material pellet or material removed from the pipe or fitting are heated and compressed between microscope slides.The specimens produced are examined microscopically and the sizes of particles and agglomerates are measured, recorded and graded by comparison with a tabulated grading system. A particle/agglomerate size grading is determined from an average of he gradings determined for six specimens.System generates rich text format report, with recorded and calculated data.